| Sign In | Join Free | My ecer.com.ru |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ecer.com.ru |

|

Brand Name : YT

Model Number : SH200

Certification : ISO9001

Place of Origin : China(Mainland)

MOQ : 1PCS

Price : Negotiable

Payment Terms : L/C,T/T

Supply Ability : 10000 PCS/month

Delivery Time : 7-30 days

Packaging Details : Standard Export Packaging

Model NO. : SH200

Product Name : Idler or Idler Wheel

Finish : Smooth

Hardness Depth : 8-12mm

Origin : China

Color : Yellow/Black

Availability : 10-15days

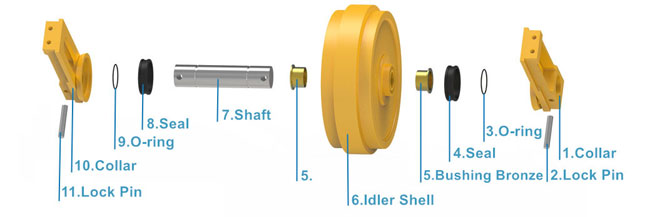

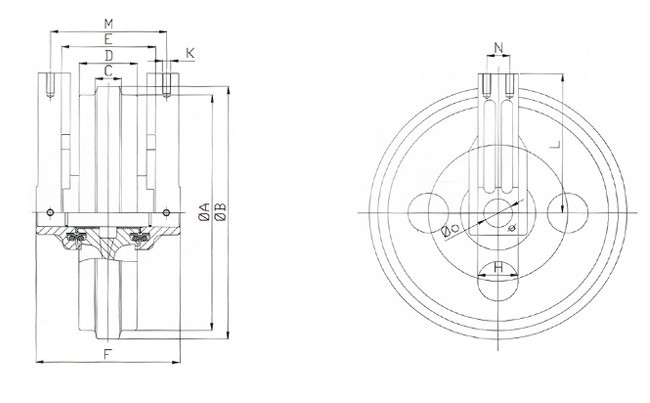

SUMITOMO SH200 Construction Machinery Bulldozer OEM Undercarriage Spare Parts Heavy Duty Front Idler Assembly

2. Idler Characteristic

4. Production Processes

5. Hot Sale Products

6. Our Advantages

World-class quality

Factory sale directly with reasonable price

35 years' experience in Excavator & Bulldozer spare parts manufacturing

Fast delivery within 30 days after contract established

Professional sales team, quality inspection and report, maritime logistics guidance

After-sale services: video technical support, 24h online support

Are you still troubled by lacking of quality excavator idler? YinTai Parts is one of the professional manufacturers and suppliers of excavator idler in China, who has high quality products for sale. With over 30 years experience and wide expertise, we can assure you the high quality and good performance of our products.

|

|

SUMITOMO SH200 Model Front Idler Assembly with 8-12mm Hardness Depth and 10-15days Availability Images |